A Driveline Vibration Damper Is Different Than A Crankshaft Damper

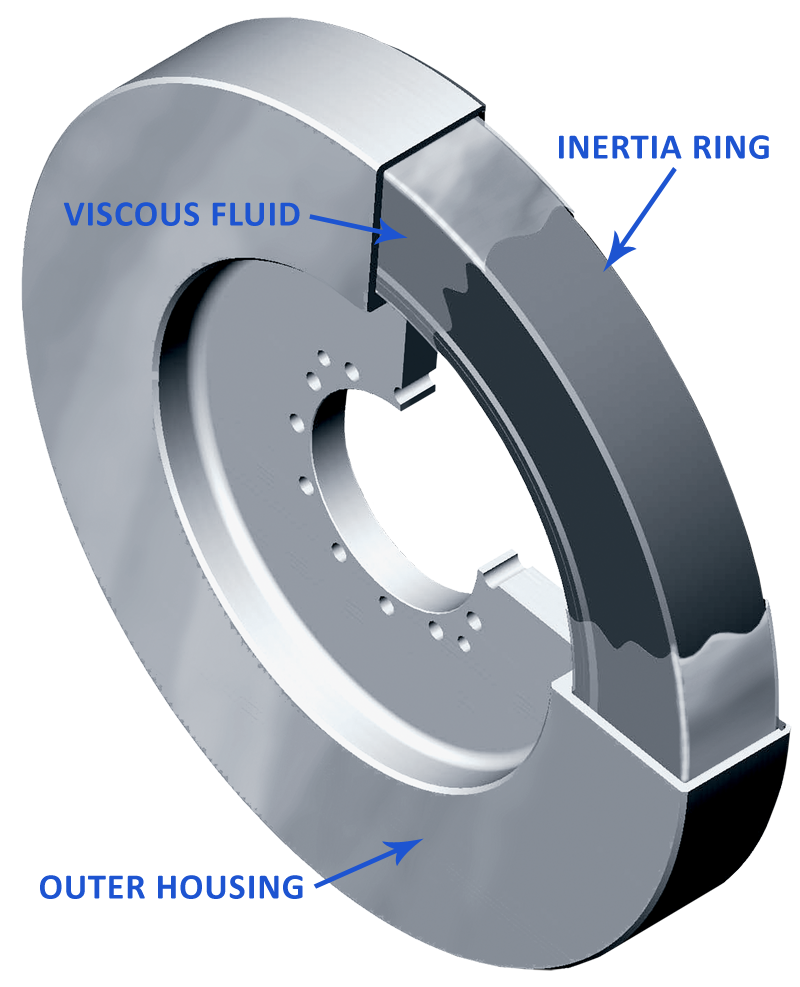

While they may appear similar in design, Vibratech TVD driveline vibration dampers are different than crankshaft dampers.

While they may appear similar in design, Vibratech TVD driveline vibration dampers are different than crankshaft dampers.

Vibratech TVD has perfected the use of silicone for over 70 years in viscous damping applications. As a vibration damping medium, silicone provides four key properties.

In our previous post, we explained torsional vibration. Torsional vibration can be categorized under Noise, Vibration & Harshness (NVH) and directly impacts powertrain performance and durabality, plus affects the operator.

In a previous post we defined a viscous damper as a fundamental component to create durability and efficiency in a powertrain system by reducing torsional vibration.